We seek to lead the field in supplies to reference customers in following strategic sectors: automotive industry, industrial vehicles, agricultural vehicles and hydraulic components.

We base our work on the principles of total quality, backed up by certificates of compliance with IATF 16949:2016, ISO 9001:2015 and ISO 14001:2015.

Solvency

Our corporate structure stresses continual investment to ensure our economic and financial solvency.

Betsaide Technical solutions in cast iron

Betsaide SAL is an established iron castings group located in the Spanish Basque Country that supplies mostly nowadays reference customers from the car and truck automotive industry.

Betsaide SAL produces since 1989 ductile iron castings, SG iron castings and austempered ductile iron (ADI) castings up to 20kg in weight using 4 DISAMATIC moulding machines with the latest generation technology.

From the early RFQ phase to the final project acquisition, Betsaide launches simulation analysis (MAGMA) to prevent serial defects and to propose design and cost-effective optimizations considering the growing exigence of the casting component requirements.

In our own tool shop, we are able to produce rapid prototypes and pre-series castings using full production processes.

Betsaide SAL is certified to IATF 16949:2016, ISO9001:2015 and ISO14001, and we are proud to invest constantly in human resources and capital equipment, looking forward to becoming your preferred partner for cast iron, machined, painted and assembled components.

We are strong, because of our corporate structure and our extraordinarily close-knit workforce. We are technologically advanced, and we have objective capabilities that enable us to provide real solutions to the problems of our customers.

We are versatile and can adapt ourselves to a wide range of technical specifications and conditions of supply and service.

We are always seeking to satisfy our customers through our character, through our experience, through our technology, through our flexibility and through our quality.

Entities with which we collaborate

Technology and equipment Always at the forefront

1 DISAMATIC 231 B Fast (2013) mould dimensions: 650 x 535 mm

1 DISAMATIC 231 Z Fast (2015) mould dimensions: 750 x 570 mm

1 DISAMATIC D3 555 B (2016) mould dimensions: 650 x 535 mm

© Disa

Sectors We are leading suppliers for major reference customers in following strategic sectors: automotive industry, heavy & light duty vehicles, agricultural vehicles and hydraulics

Automotive industry

We supply to Tier 1 suppliers, top-level manufacturers and global references companies.

Heavy & light duty vehicles

We supply directly to several front-line OEMs. We are growing with new projects by the hand of our OEM and reference Tier1 customers.

Agricultural vehicles and machinery

We supply both OEMs and their Tier 1 suppliers.

Valves / Hydraulics

We are seeking to reinforce this product sector, where we have long-time customers, by manufacturing high quality, high performance components.

Miscellaneous

We also supplied to other major sectors including railways, lifting systems, electrical systems, transportation and hand tools.

Products Materials and added value

Spheroidal graphite cast iron.

Austempered Ductile Iron (ADI):

• Weight range: 150 g – 20 kg.

• Supply of raw castings & finished components.

Additional services:

• Precision machinings.

• Surface coatings.

• Heat treatments.

• Assemblies.

Spheroidal graphite cast iron according UNE EN 1563

| EN-GJS designation | Tensile strength N/mm2 | Yield strength N/mm2 | Minimum elongation % |

|---|---|---|---|

| EN-GJS-400-15 | 400 | 250 | 15 |

| EN-GJS-400-18 | 400 | 250 | 18 |

| EN-GJS-450-10 | 400 | 310 | 10 |

| EN-GJS-500-7 | 500 | 320 | 7 |

| EN-GJS-500-14 | 500 | 400 | 14 |

| EN-GJS-600-3 | 600 | 370 | 3 |

| EN-GJS-600-10 | 600 | 470 | 10 |

| EN-GJS-700-2 | 700 | 420 | 2 |

| EN-GJS-800-2 | 800 | 480 | 2 |

Austempered Ductile Iron (ADI) according UNE EN 1564

| EN-GJS designation | Tensile strength N/mm2 | Yield strength N/mm2 | Minimum elongation % |

|---|---|---|---|

| EN-GJS-1000-5 | 1000 | 700 | 5 |

| EN-GJS-1200-2 | 1200 | 850 | 2 |

| EN-GJS-1400-1 | 1400 | 1100 | 1 |

R&D&i Technical solutions, co-engineering and innovation

Design (CATIA V5 , SOLIDWORKS).

Predictive smelting techniques & simulation (MAGMASOFT).

Fast, in-house production of prototypes.

In-house workshop: construction, modification, reworking & maintenance of toolings.

In-house core making (7 x cold-box machines).

State-of-the-art nodularisation, moulding & inoculation control equipment.

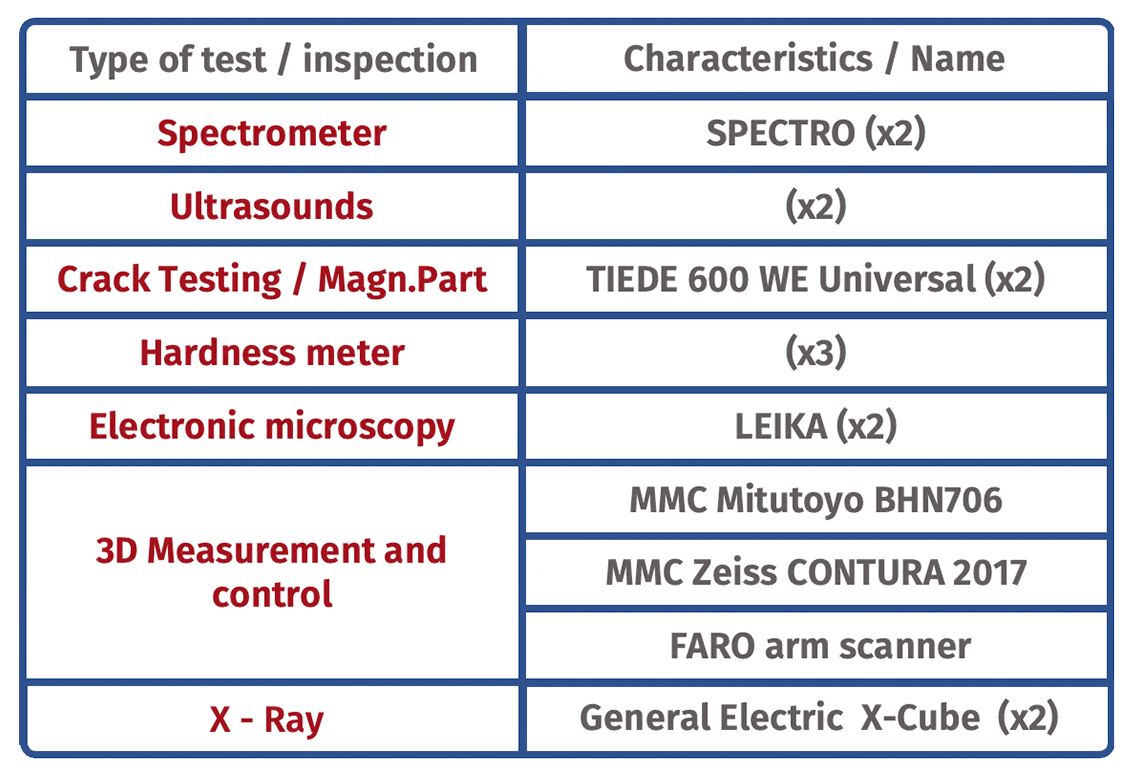

In-house control & testing equipment.

Ongoing cooperation with technology centres in R&D&i, projects and technical assistance.

Quality certifications Towards total quality

News Our latest news

We visit KL katealegaia

Contact -

Coordenadas GPS:

N 43°07'39.6" | W 2°32'22.5"

Business Contact

BETSAIDE

Betsaide, 1

48230 Elorrio (Bizkaia)

Tel.: +34 94 658 45 60

Fax.: +34 94 658 45 61

info@betsaide.com